Mixers & Agitators

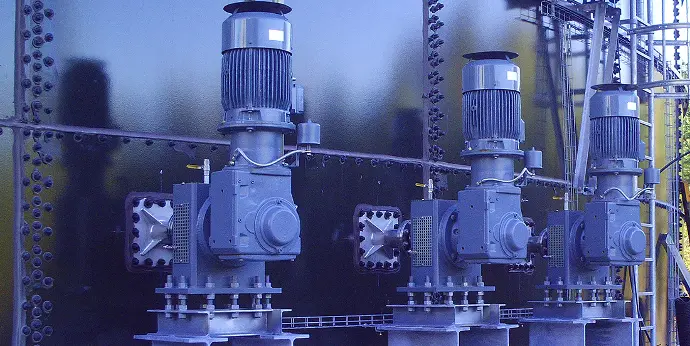

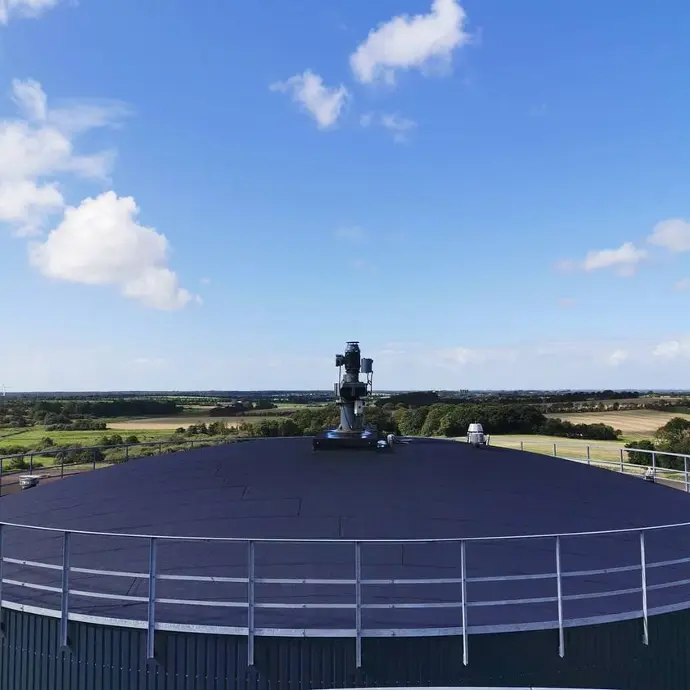

AFROVEN do represent Future Engineering AB specializes in the design of custom made Mixers, Agitators and Steel Tanks of various Sizes, either welded or bolted, Future Engineering develops, manufactures and supplies the appropriate mixing solutions for Waste Water and Biological Waste Plants.

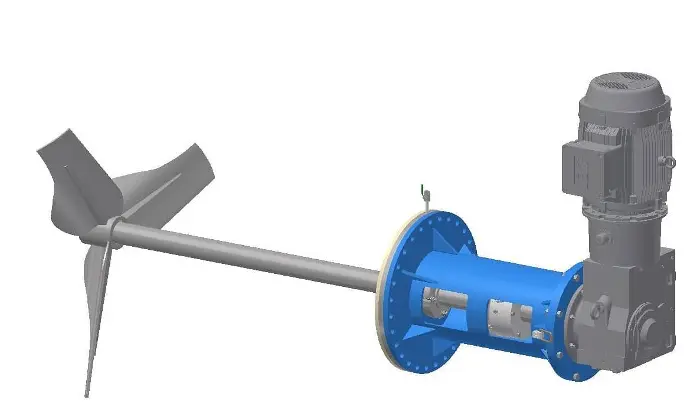

FUTURE ENGINEERING High efficiency Super-max-flow Impeller provides the following operational advantages.

- Low glide number along the entire blade surface

- High pumping capacity

- Up to 30% lower energy consumption

- Insensitivity to viscosity variations

- Low installation costs

- Peak technology for biogas reactors including swim layer breaking equipment

Wetted parts are available in Carbon Steel, Stainless Steel, Acid Proof Steel, and in many other alloys. In certain applications, wetted parts are coated with Teflon, PVC, Haler, PVDF or in other materials based on the application.

We are designing Agitators / Mixers for volumes 0,1 m³ - 50,000 m³.

Future Engineering has developed “excellence” in mixing technology which ensures a more efficient and cost-effective blending process, using one of the most energy efficient impeller design available, Super-Max-Flow-Propeller™ used in all our range of mixers like Top, Side or Bottom entering mixers and in special applications several propellers and / or turbines can be mounted on the same mixer in combination with anchor-mixers and dissolvers. In addition we can also offer straight angled propellers or a various number of turbines (HD-turbine / Rushton-turbine) when a higher degree of shear rate is desired.